Aftermarket Services

Through our service division, PolSys Services, we can provide total service solutions for your air pollution control equipment. We offer a full suite of maintenance and repair services for any needs you may have on our equipment or equipment provided by another manufacturer.

Control Upgrades

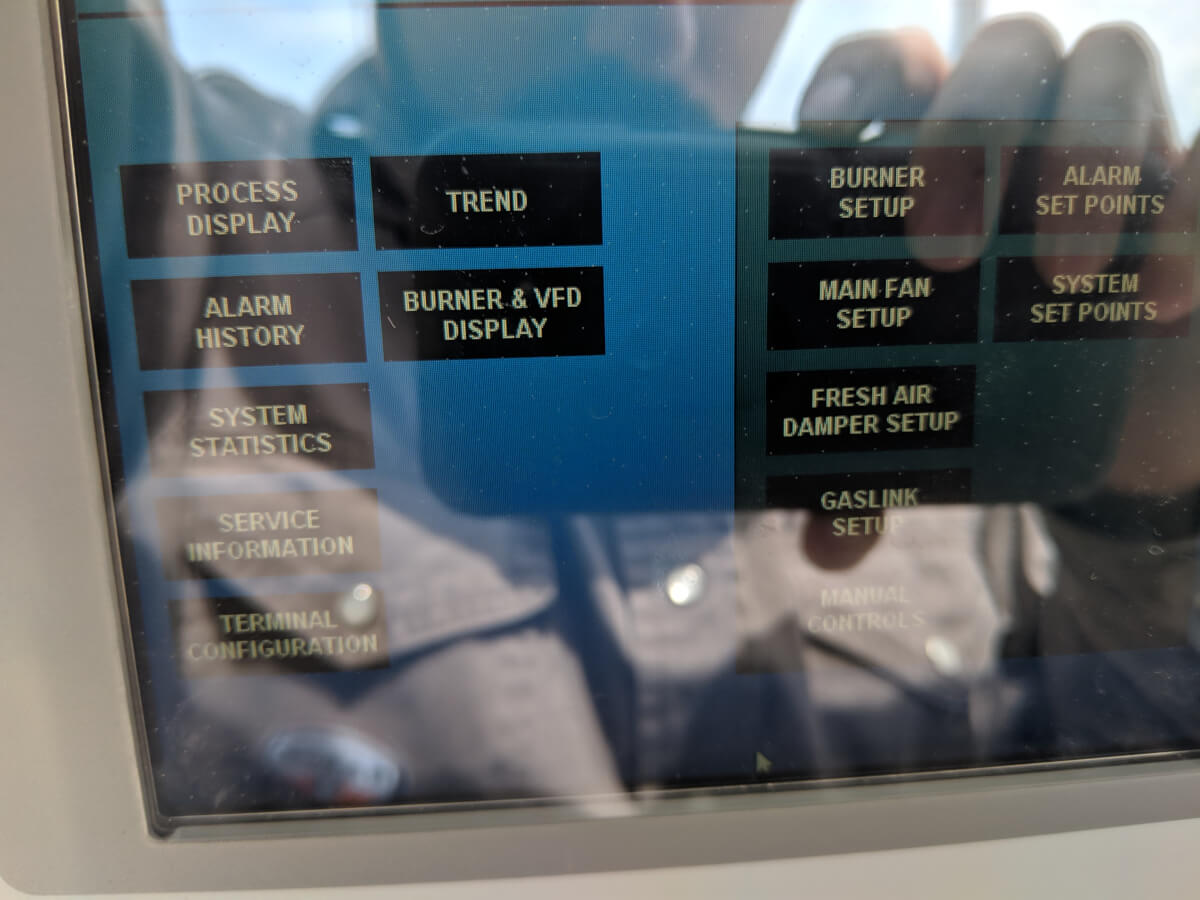

Control system design is vital to process equipment reliability, functionality, and efficiency, so consider control upgrades if your current APC system lacks contemporary/modern PLC technology. Newer PLC models offer advanced features that enable faster prediction and prevention of system issues, enhancing safe operation and compliance. These can also improve operational efficiencies and data collection, providing real-time key performance indicators for everything from PMS management to business analytics.

Close-up View of Control Interface Screen on a Regenerative Thermal Oxidizer System

Retrofitting and System Upgrades

Project Managers Surveying Site During Air Control System Upgrade at an Existing Industrial Facility

For some plants, retrofitting or upgrading existing equipment may be the most suitable solution for your plant in the short term. Unfortunately, there is no one-size-fits-all approach to altering existing pollution control systems to achieve higher destruction efficiencies. Many factors must be considered, including a facility’s operational goals, DRE requirements (or expected new requirements), waste stream, and existing process limitations. Some abatement equipment will allow for simple modifications or minor adjustments, while others may require extensive retrofits.

System Relocation

Sometimes, relocation upgrades from one location to another makes the most economical sense for your business. Proper relocation of air pollution control equipment is imperative to the long-term performance and reliability of a system. We have extensive, hands-on experience with installations, system start-ups and commissioning to ensure that your industrial equipment is installed properly and meets the design standards for operation.

Pollution Systems Recuperative Thermal Oxidizer Is Positioned into Place Using a Crane During a System Relocation

Need Aftermarket Support?

We are still here for you even after your APC project is done. We can help you with any service needs for your equipment.

Frequently Asked Questions

Yes, we provide all of the NFPA-mandated safety interlock testing and on-site inspections for any make and model of air pollution control equipment. Please note that our aftermarket services require this for all our first-time customers.

While we do offer this service and can work remotely on almost any system, this is dependent on the remote automated controls package it may have.

Our service group offers nationwide support in the United States and, in some cases, internationally. We will inspect your system and provide a detailed report on any findings and recommendations. We inspect all parts of your system, including:

- System components

- System controls & gauges

- System temperatures

- Control Panel

- Fuel regulators

- Key parts and instruments

- Interlocks

- Monitoring devices

- Valves and Switches

- Strainers and more