Multi-Vane Scrubber Captures Problematic Particulate at Food Facility

- Pollutant: Particulate Matter (PM)

- Industry: Food Processing & Manufacturing

- System: Wet Scrubbers

Using a Multi-Vane Scrubber, a food manufacturer abates particulate emissions from their food processing line.

Synopsis

In 2015, a food facility needed an air pollution control system to reduce the particulate dust emissions discharged into the atmosphere from its plant. The end customer collaborated with an outside engineering company that recommended using a venturi scrubber. Pollution Systems (PSI) analyzed the application process and determined that a Multi-vane Scrubber would be the best choice to solve their issue.

Initial Operating Issue

The facility’s process application emitted a waste stream of particulate dust from two dryers at a variable flow rate. The system had to be sized to accommodate a 41,200 ACFM discharge due to the variability in flow rate. The waste stream also had 30% water content and 90% relative humidity, so every part in contact with the food-grade product needed to be of AISI 304L Stainless steel construction. The high-water content brought concerns about possible particulate build-up in the scrubber.

Other system requirements included:

- Guaranteed removal efficiency to achieve their permit requirement of ≤5 mg/Nm3

- Efficient water & electrical usage

- Easy-to-maintain and self-cleaning properties

- Conform to all applicable OSHA requirements

- High on-stream operating time

- Clean-In-Place (CIP) system

- Operator Safety was a top priority

Proposed Solution

After carefully reviewing the facility’s variable process flow rate and composition, Pollution Systems proposed installing their Multi-Vane Scrubber System, Model #MVS-41. An advanced scrubber with a proprietary design, the MVS is better suited for treating large flow volumes than a venturi scrubber. It provides 99% removal efficiency of particulate matter (PM) from batch and continuous operations and prevents internal sticky build-up. MVS scrubbers are backed technologies with no internal moving parts; other than a system fan and recirculation pump, the equipment is solid state and, therefore, simple to maintain.

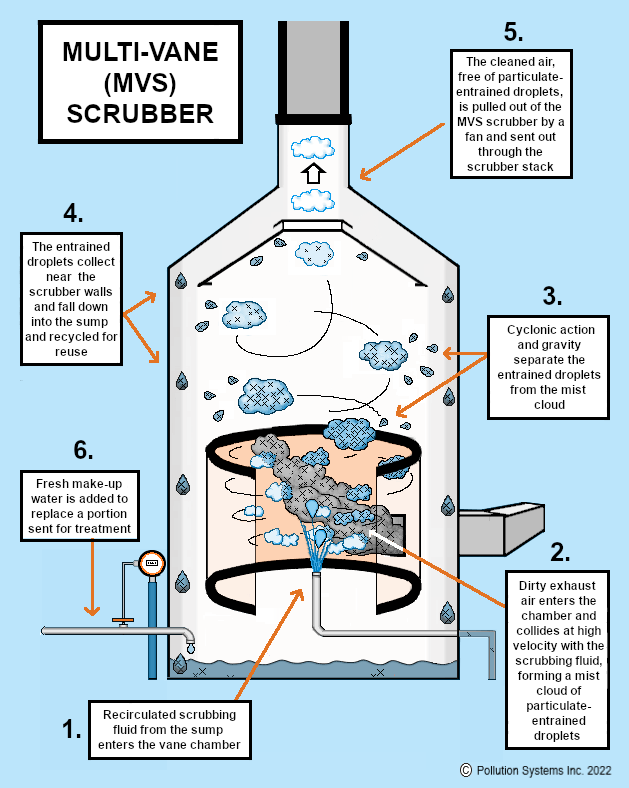

MVS Technology: How it Works

The MVS-41 is a self-contained, venturi-style scrubbing system. Its internal multi-vanes act as multiple venturi throats and are engineered to handle large process flows.

Water, recirculating from the sump, collides with the dirty exhaust and is sheared into a fine “cloud” of droplets in the multiple throats of the system. This high-velocity cloud constantly impinges and impacts the vanes, capturing the particulate inside the droplets. The circular rotation, coupled with vigorous movements within the chamber and sump, prevents dead zones that can lead to build-up on the vanes.

The unique design and MVS technology discourage any particulate build-up on the scrubber’s internal parts. Additional benefits include:

- Recirculated water minimizes water usage, saving money and resources

- Inherent self-cleaning minimizes system downtime

Implementation

Pollution Systems successfully executed their 4D process to deliver a Multi-Vane Scrubber Model# MVS-41 system, which met all the client’s requirements.

PSI designed the system to operate with a noise level of less than 80 dB(A) at 4 feet to protect personnel; incorporated equipment guarding to protect operators from moving components; and placed instruments and motors at least 3’ away from inspection doors, manholes, and other high-traffic areas to optimize safety. Automated controls kept the MVS running smoothly.

Although the MVS is inherently self-cleaning, including a Clean-In-Place system (CIP) ensures strict conformance with industry standards.

Results

The MVS-41 system met the client’s goals of removing >99% of particulate and ensuring additional safety features. The system performed so well that the customer installed an additional Multi-Vane Scrubber the following year at another one of its facilities.

Related Case Study

Food Manufacturer Resolves Process Complications With a Multi-Vane Scrubber

A food manufacturer experienced continuous operational issues due to wet, sticky particulates present in their cereal processing application. Pollution Systems designed a Multi-Vane Scrubber to successfully abate the PM build-up with minimal maintenance needs.

- Pollutant: Particulate Matter (PM)

- Industry: Food Processing & Manufacturing

- System: Wet Scrubbers