Industry Solutions

Explore the technology solutions that Pollution Systems recommends for emission control in your particular industry.

View All Industries

Explore the technology solutions that Pollution Systems recommends for emission control in your particular industry.

Transportation Electrification

In hopes of decarbonizing the transportation sector, electrification of vehicles is on the rise and manufacturing of the critical components needed to advance the industry requires adequate air control systems.

Recovery & Recycling

Innovative processes to recover or recycle used materials economically have been emerging to combat environmental impacts of waste. Emission control is often necessary due to the regulated pollutants that can be present in these recovery processes.

Ethylene Oxide Treatment

Ethylene Oxide (EO or EtO) has become the sterilization method of choice for medical devices. Our air control systems abate EtO emissions from contract sterilization facilities and can achieve 99.9% destruction rate efficiency (DRE), or 0.2 ppm of EtO, from process air streams.

Food Processing & Manufacturing

Increasingly stringent regulations for food manufacturing and processing operations calls for cost-effective, reliable equipment that meets the air requirements necessary to continue production.

Tank & Pipeline Degassing

The degassing industry is at the forefront of a shift in operating procedures and the use of supporting technology. It is imperative to have safe, high-tech, and reliable air control equipment that accommodates more business for your bottom line.

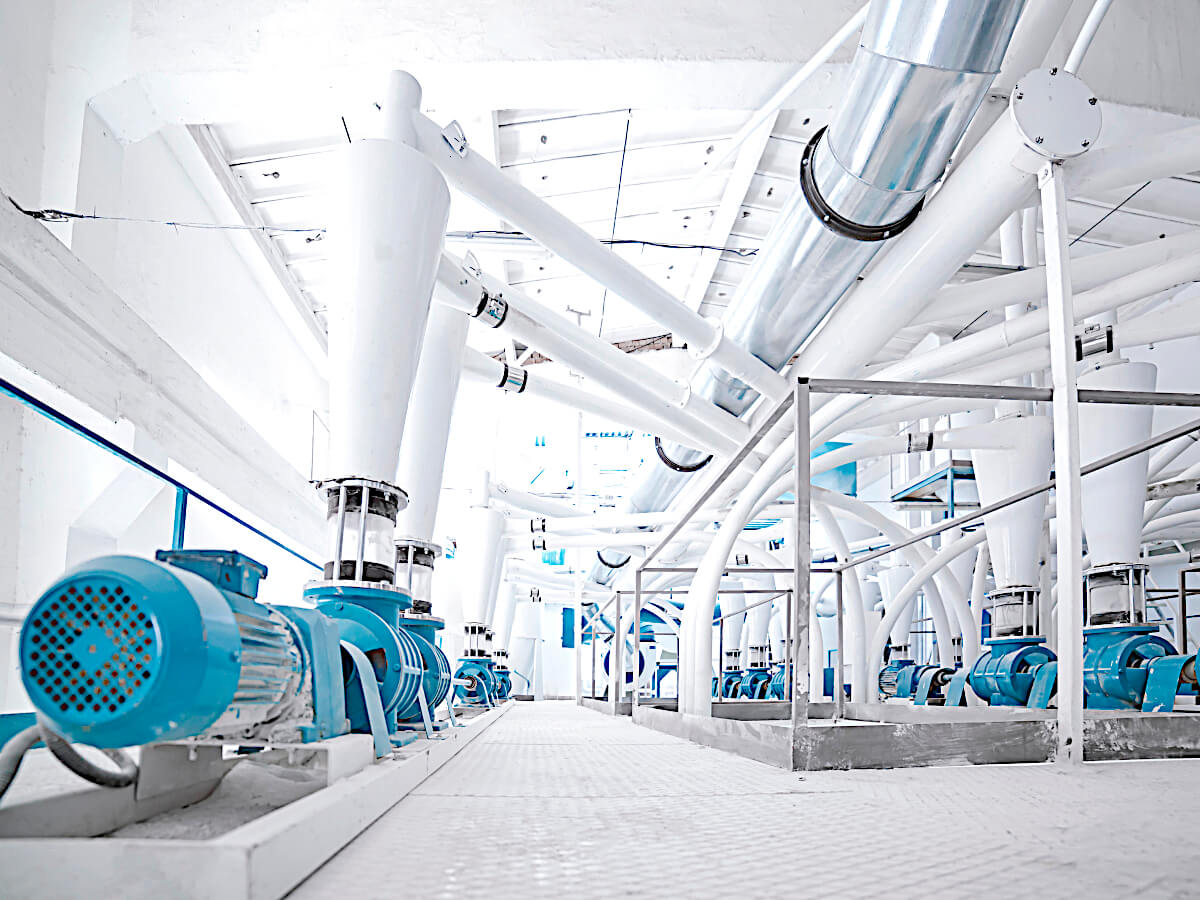

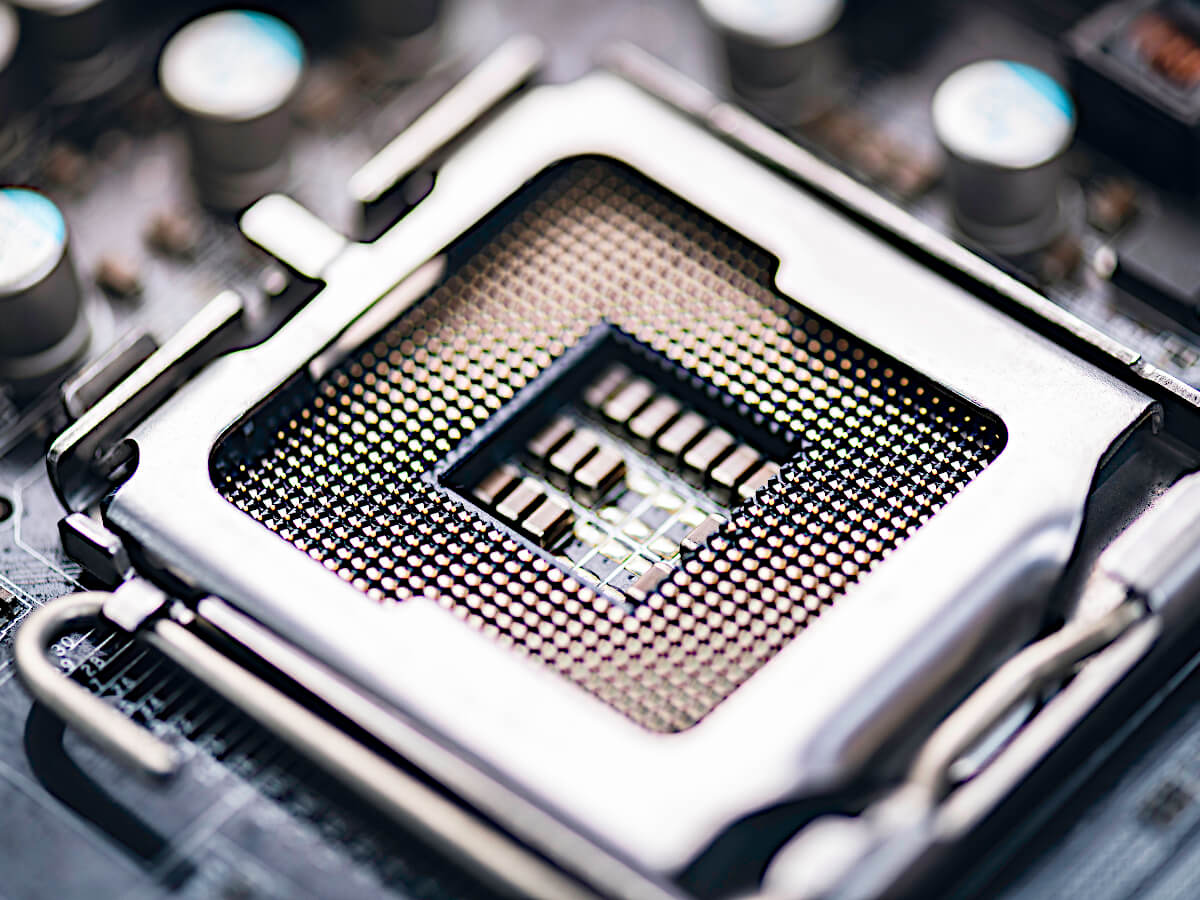

Microelectronics

In order to create microelectronics like chips and semiconductors, metals, minerals, and chemicals are utilized during manufacturing, which can result in emissions of PM, VOCs, and HAPs.

Building Materials

Manufacturers strive to produce building materials that create safer and more durable buildings and infrastructure. However, even greener practices can produce some VOC, HAP, or PM.

Pharmaceuticals

Pharmaceuticals have been and continue to be instrumental in the protection of our population’s health; however, many of the industry’s formulations contain carriers and other organic solutions that evolve into toxic air pollutants during production.

Metal Finishing

Metal finishing operations can have particulate matter (PM), volatile organic compounds (VOCs), and hazardous air pollutants (HAPs) in their process air streams. These pollutants require treatment before discharge.

Biofuels

Biodistillate fuels, which are renewable, are critical to the development of a sustainable fuel supply. The processing of biomass to create these renewable fuels can generate air pollution that requires treatment before discharging to the atmosphere.

Mineral Processing

Due to the handling of minerals and grinding required during processing, these operations generate high levels of dusts and particulate matter. Other mineral processing activities, such as leaching, release VOCs, HAPs, and other regulated pollutants.

Petrochemical Processing

Used extensively in the creation of today’s products, petrochemicals are necessary building blocks in industrial manufacturing. Their use leaves residues that contain volatile vapors and other regulated pollutants in the process exhaust streams.

Midstream

Midstream activities encompass processing & treatment, storage, and transportation; the operations within each of these activities can emit VOCs and HAPs that require emission control technologies.

Don’t See Your Industry?

Our diverse experience allows us flexibility to adapt our air control solutions to industrial processes that may not be captured above. Provide us with your application details, and we will work with you to develop a tailored solution for your process.