Food Processing & Manufacturing

Food Industry Compliance

Food operations are subject to increasingly stringent regulations from all levels of government on air emissions as well as community pressures to solve unregulated issues such as odor control; successful companies recognize that many stakeholders need to be satisfied or face negative business consequences, including penalties and negative publicity.

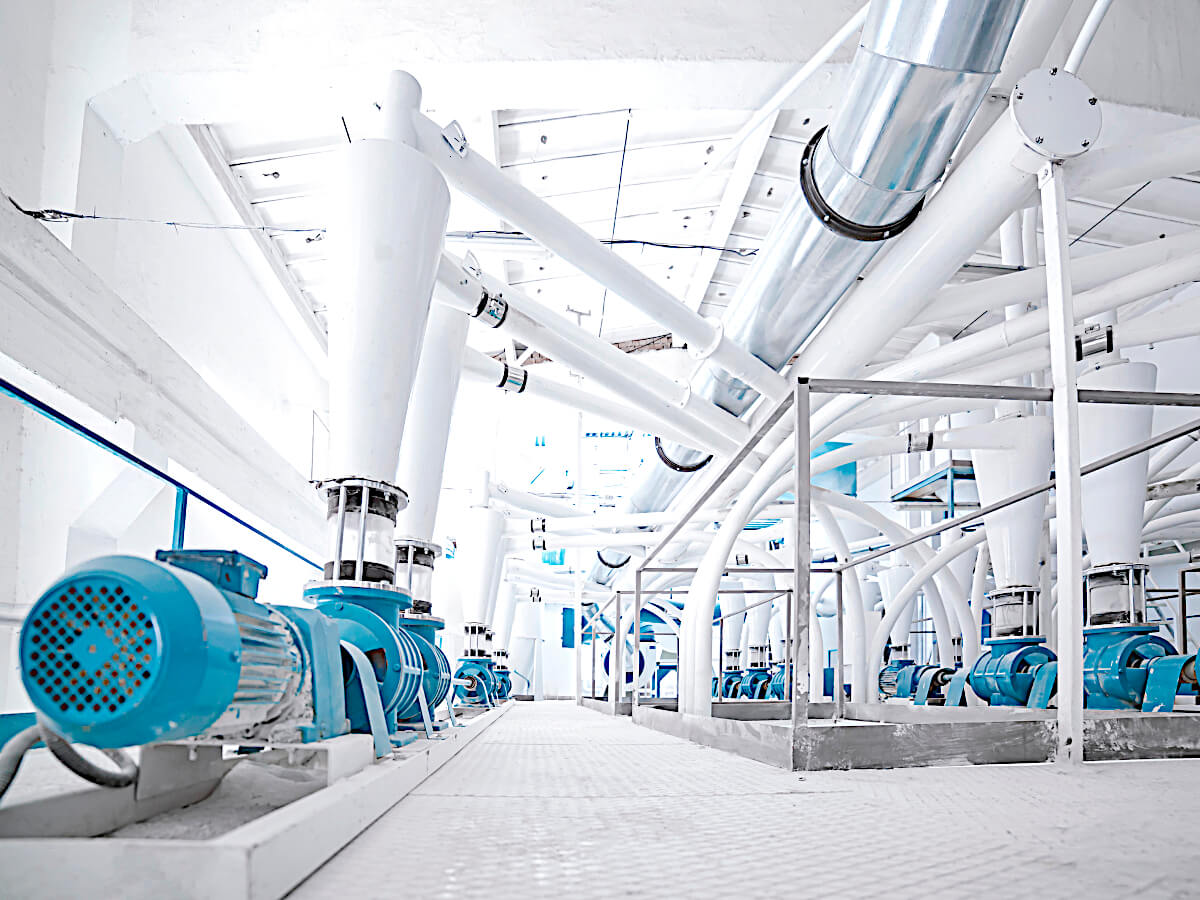

Strict hygiene mandates are followed at a clean food processing plant

The highly competitive nature of the industry, as well as the need to keep stakeholders satisfied, means manufacturers must be diligent in selecting cost-effective, reliable equipment that meets the air pollution control requirements to keep their operation running smoothly and maintain a positive reputation.

Food Manufacturing

Pollution Systems recognizes that each operational problem is unique and that the tailored solution must meet governmental regulations while supporting the individual plant’s production and operational goals.

A grain processing plant produces flour for cereal and bakery products

Our roots in industrial-grade equipment allow us to steer customers through the complicated array of technologies and provide them with comprehensive solutions that will give lifetime satisfaction.

Our systems have solved a broad range of challenging issues, such as VOC treatment, odor control, and removing particulate matter (including PM 2.5 or PM 10) from food manufacturing, including the drying and cooking processes. Each solution is designed to meet your company-specific permit and safety requirements and includes a performance guarantee.

Animal Feed

Animal feed processors have similar issues regarding airborne VOCs, odors, and particulate matter that they must control. Dust particulate (including PM 10 and PM 2.5) may enter the exhaust stream during the grinding and drying processes. Unpleasant odors may generate during manufacturing or processing. VOCs may also evolve during the manufacturing or drying process. Pollution Systems offers solutions to remove the odor, particulate, and VOCs from the exhaust stream to keep your facility compliant with its permit.

Stainless steel grain silos at animal feed processing plant

Air Pollution Equipment for Food Processing

Efficient MVS Scrubber captures moist particulate at food facility

Typical air control solutions for the food and feed industry include Wet Scrubbers and Thermal Oxidizers:

- Multi-Vane Scrubbers – ideal for fine particulate (PM 2.5) removal and used by our customers in cereal and yeast manufacturing.

- Venturi Scrubbers – its clean-in-place system makes it very effective in grease or oil-laden air emissions, and our customers effectively use them to treat exhaust from meat cooking.

- Chemical Scrubbers – very effective for controlling many odors formed in food or food waste processing.

- Catalytic Oxidizers – suitable for cleaner air streams that need treatment of odor or VOCs in bakery or coffee roasting applications.

- Recuperative Thermal Oxidizers – compatible with higher-temperature drying processes, it uses combustion to neutralize odors in the exhaust that contains high levels of particulate or VOCs.

Every system is engineered and built specifically for each application and includes Automated System Controls to optimize efficiency, reliability, safety, and ease of operations while reducing operator interaction.

Wet Scrubbers or Oxidizers Tailored to Your Food Process

Meeting regulatory challenges with minimal operational interference can be a strategic asset, and Pollution Systems can provide you with a holistic solution that meets the unique specifications of your industrial food processing and manufacturing application.

Related Case Studies

Venturi Scrubber Removes Sausage Grease From Industrial Cooking Process

Pollution Systems VS-3 Venturi Scrubber effectively removes grease and particulate from air exhaust at meat processing plant.

- Pollutant: Particulate Matter (PM)

- Industry: Food Processing & Manufacturing

- System: Wet Scrubbers

Food Manufacturer Resolves Process Complications With a Multi-Vane Scrubber

A food manufacturer experienced continuous operational issues due to wet, sticky particulates present in their cereal processing application. Pollution Systems designed a Multi-Vane Scrubber to successfully abate the PM build-up with minimal maintenance needs.

- Pollutant: Particulate Matter (PM)

- Industry: Food Processing & Manufacturing

- System: Wet Scrubbers