Food Manufacturer Resolves Process Complications With a Multi-Vane Scrubber

- Pollutant: Particulate Matter (PM)

- Industry: Food Processing & Manufacturing

- System: Wet Scrubbers

A food manufacturer experienced continuous operational issues due to wet, sticky particulates present in their cereal processing application. Pollution Systems designed a Multi-Vane Scrubber to successfully abate the PM build-up with minimal maintenance needs.

Synopsis

A major U.S. food manufacturer desired a second particulate abatement system for particulate emissions that resulted from manufacturing processes at their dried cereal production facility in the Southeast. The first abatement system, manufactured and installed by Pollution Systems on the non-gluten production side of the plant, has operated well since 2016, resulting in significant particulate removal to aid in the elimination of biological growth on the facility roof.

Initial Operating Issue

When this food manufacturer first contacted Pollution Systems in 2014, they had unsuccessfully used scrubbers to treat particulate emissions from their product application; however, they had continual problems with these systems due to the build-up of wet, sticky residue on the roof. This build-up required constant, manual removal to maintain performance. The manufacturer sought a viable system with high uptime and reliability to eliminate the problematic discharge and withstand both batch and continuous operating requirements.

Other system requirements included guaranteed removal efficiency, efficient water & electrical usage, easy maintenance, self-cleaning properties, and incorporated freeze protection.

Proposed Solution

After carefully reviewing the facility process application, Pollution Systems proposed the installation of their Multi-Vane Scrubber System, Model #MVS-54. An advanced scrubber with a proprietary design, the MVS allows for 99% removal efficiency of particulate matter (PM2.5) from batch and continuous type operations and would solve the issue of wet, sticky build-up and biological growth.

Pollution Systems’ MVS Scrubbers are proven technology with no internal moving parts. Other than a system fan and recirculation pump, the equipment is solid state and therefore simple to maintain.

MVS Technology: How it Works

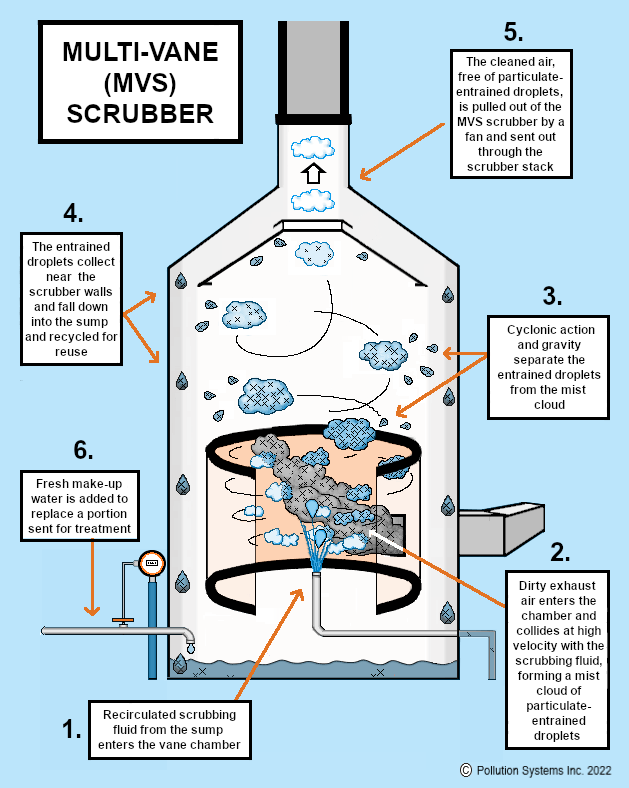

The MVS-54 is a self-contained, venturi-style scrubbing system. Its internal multi-vanes act as multiple venturi throats and are engineered for specific particulate removal efficiencies as a function of particle size (μm) and pressure drop (ΔP).

Water recirculates from the sump and shears into a fine mist/cloud of droplets in the multiple throats of the system. This high-velocity cloud constantly impinges and impacts the vanes and keeps them clean of particulate build-up.

Downstream of the vanes, cyclonic action removes the particulate-entrained water droplets from the airstream. The liquid droplets then return to the integral sump for reuse.

The thoughtful design of Pollution Systems’ MVS Scrubber discourages any particulate build-up on the system parts. Additionally, the MVS system efficiently uses water as the cleansing agent, continually recirculating it to minimize water usage. These are fundamental characteristics of the MVS.

Implementation

At first, the food manufacturer was skeptical about using another scrubber system, but Pollution Systems offered a pilot MVS System unit to demonstrate the technology. Based on the performance of the pilot unit and before committing to a permanent solution, the manufacturer decided to further test Pollution Systems’ Multi-Vane Scrubber System by installing an abatement unit on one (1) of the four (4) non-gluten roll dryer process lines, alongside a competing system for comparison. When Pollution Systems’ MVS System successfully outperformed the competing unit and alleviated any remaining concerns, the manufacturer awarded Pollution Systems the project and purchased a custom abatement system for four (4) of their eight (8) roll dryer lines.

Results

Today, the equipment is still operating well and is highly effective at removing the wet, sticky particulate and eliminating the need for constant manual cleaning. Pollution Systems’ MVS Scrubber System demonstrated such success in particulate abatement and maintaining >99% DRE that the customer decided to install a second, identical particulate abatement system for the glutenous side of their operations. This new project was a permanent solution for the remaining four (4) of the eight (8) roll dryers.

Related Case Studies

Food Manufacturer Resolves Process Complications With a Multi-Vane Scrubber

A food manufacturer experienced continuous operational issues due to wet, sticky particulates present in their cereal processing application. Pollution Systems designed a Multi-Vane Scrubber to successfully abate the PM build-up with minimal maintenance needs.

- Pollutant: Particulate Matter (PM)

- Industry: Food Processing & Manufacturing

- System: Wet Scrubbers

Venturi Scrubber Removes Sausage Grease From Industrial Cooking Process

Pollution Systems VS-3 Venturi Scrubber effectively removes grease and particulate from air exhaust at meat processing plant.

- Pollutant: Particulate Matter (PM)

- Industry: Food Processing & Manufacturing

- System: Wet Scrubbers